- Siruganur

- +91 77082 11811

- mampc@yahoo.com

M.A.M. Polytechnic College was founded by Thiru. M.ABDUL MAJEDU is one of the recognized Technical Institution in middle region of Tamilnadu offering technical education especially to the rural community. The college is approved by AICTE and affiliated to Directorate of Technical Education, Chennai and also an ISO 9001 : 2008 certified Institution.

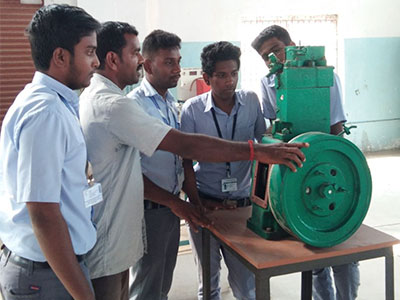

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., micro scale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed.

The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure. Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion.

To put it simply, mechanical engineering deals with anything that moves, including the human body, a very complex machine. Mechanical engineers learn about materials, solid and fluid mechanics, thermodynamics, heat transfer, control, instrumentation, design, and manufacturing to understand mechanical systems. Specialized mechanical engineering subjects include biomechanics, cartilage-tissue engineering, energy conversion, laser-assisted materials processing, combustion, MEMS, micro fluidic devices, fracture mechanics, Nano mechanics, mechanisms, micro power generation, teratology (friction and wear), and vibrations.

To be a world class institution leading to provide technological skills and innovative approaches to become a professional engineer by ensuring high quality technical education to all sections of students.

Impart technical knowledge and skills to students towards continuous improvement in education and placement and prepare the students to meet the challenges in the technical advancement to serve the community.

MAMPC is committed to provide the value based education in Engineering and Technology to achieve quality excellence with continuous improvement in education and placement focusing on moral, ethical and social values to our students to fulfill their obligations to the society and nation at large.

Engineers (ASME) currently lists 36 technical divisions, from advanced energy systems and aerospace engineering to solid-waste engineering and textile engineering

| Sl No | Date | Semester | Resource Person | Topic |

|---|---|---|---|---|

| 1 | 27/12/2017 | II / IV | Mr.Rajesh, Executive Manager, CADD Center, Trichy | Emerging Trends in Mechanical Engineering |

| 2 | 04/01/2018 | II / IV | Mrs.Vanitha, CAD Engineer, CADD Center, Trichy | Geometric Modeling Techniques by using CAD/CAM |

| 3 | 04/01/2018 | III / VI | Mrs.Vanitha, CAD Engineer, CADD Center, Trichy | Geometric Modeling Techniques by using CAD/CAM |

| 4 | 06/01/2018 | III / VI | Mr.Sakthivel / Executive Manager, New CNC Institute, Trichy | Basics Of PLC And How PLC Is Programmed |

| 5 | 03/02/2018 | III / VI | Mr.Mahesh, Team leader, CADD Centre, Trichy | Advanced Rapid Prototyping Technologies |

| Sl No | Semester | Date | Name of the Company |

|---|---|---|---|

| 1 | II / III | 22/08/2017 | Diesel Loco Shed, Senthaneerpuram, Trichy |

| 2 | III & V | 22/08/2017 | Diesel Loco Shed, Senthaneerpuram, Trichy |

| 3 | III & VI | 19/01/2018 | GK Industries, Trichy |